Sail winches, which type?

A new skipper recently asked me, " I am thinking of getting a 1 meter boat and have no idea how strong the sail servo should be." He's also asked should he use a drum winch or a sail arm winch

A new skipper recently asked me, " I am thinking of getting a 1 meter boat and have no idea how strong the sail servo should be." He's also asked should he use a drum winch or a sail arm winch

|

Here's a picture of a drum winch

|

Here's a picture of a single sail arm winch

|

I'll quote his message and try to answer a very complex question as best I can...

A lot of what he's trying to learn is also dependent on his frame of reference and what he already knew about RC yachts and sheeting systems.

Several factors determine whether to use one or the other, How is the boat going to be used? Full out racing or more of a fun boat? How much does the skipper have to spend on radio gear? Also this really depends on the set of sails and the wind conditions you're going to sail in. And how complex a building / rigging job do you want? But, here goes.

I'll try my best to help, culling information from some good sources, Model Yachting Magazine issues #119 and #120 both reference one meter class boats, the US1m and Soling 1M respectively.

The details as I know them. The US 1M is limited to 600 Sq in of sail area, the Soling 1m is rated at 592 sq in of sail. Both boats can be configured with either a drum or sail arm sail winch.

Sail arm seems to be preferred in the Soling 1M, I presume for ease of construction and installation and to save money. The same should apply to US 1M's, though I saw many drum winch servos at the US 1M National Regatta in San Diego in August of 2000.

A Soling 1m article in MY issue #120 mentions the use of the Futaba 3801 arm winch and says it's too fast, but not enough rotation. But, in MY issue #119, Rich Dannenhoffer had an article on how to easily convert the Futaba 3801 sail arm servo from 90 degrees to 180 degrees of travel.

Now personally, I have a Soling 1m with a Victor sail winch and agree that it seems to have too little travel, but I sail and have fun with it. It just doesn't let the sails fully out in a full 90-degree wind on wing, though I can get a wing on wing. Some articles I've read say you don't really need that full 90 degree sail opening.

I have a US 1M coming they recommended the Hitec 725BB Drum Winch Servo since I prefer Hitec products and wanted to try a drum winch setup in a one meter, just my choice.

It's rated (using a 6V receiver battery like the Hobbico NiMh batteries, which can be fully charged with any 4.8 receiver battery charger, just takes longer) to do 3.5 turns, does 1 turn every 1.3 seconds and has 193oz/in+ torque.

> Does speed of the servo matter?

Yes, if you want to sheet in faster you need a faster servo. But remember to compare oranges to oranges, some servo ratings are at 6 V and some are at 4.8 V.

> Any advantage or disadvantage to a drum winch other than cost.

Drum winch setups can be rigged in a narrower space. The complexity of the rigging seems tougher for some skippers in dealing with drum winches, though some arm winch setups with double (or greater purchase) get to be more complex than any drum arrangement.

> What about the degree of travel?

This is in reference to a sail arm servo, and this can also depend on the boat the servo is being setup in. And it's controllable by several factors, simple geometry (a long arm will pull more sheet in, a double purchase setup will pull even more. There are some simple conversions that can adjust the degree of travel and some plug-in electronic devices that can adjust the degree of travel, some radios even have adjustable end points.

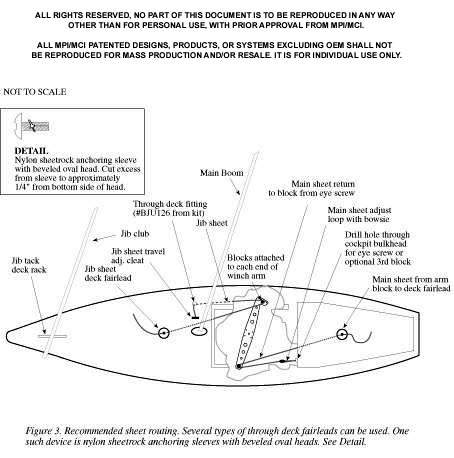

Remember, (or learn) there's a difference between a single arm setup and single purchase, and between a double arm setup and double purchase. The Soling 1m single arm setup on the You Asked page has a single purchase for the jib sheet and a double purchase for the main sheet, but a single arm setup. CR-914's come with a single arm sail servo, and use a single purchase setup too.

If it's a wide boat then a double arm can be used and a long arm can be mounted to it. I've even seen an offset double arm where the side of the arm feeding the main was longer than the side feeding the jib.

Determining Winch Arm Length

(From MY #66, Credited to Don Prough of Probar Design)

1. Connect the sheet line to the boom in the manner you plan to use while sailing.

2. Run the line into the boat through the fairlead.

3. Hold the boom in the "full in" position, and make a mark on the sheet line at the point where it enters the fairlead. Obviously, the line should be taut, and four hands are better than two!

4. Hold the boom in the "full out" position and make a mark on the sheet line as before.

5. Measure the distance between the two marks and:

a. For a single purchase arrangement, divide the distance by two, This is the length of the winch arm from the center of your winch's output shaft to the center of hole in the arm though which the sheet line will pass.

b. For a double-purchase arrangement, divide the distance by four and

add 1/4 inch to the result. This is the length of the winch arm from the center of your winch's output shaft to the center of hole in the arm though which the sheet line will pass.

6. Repeat the process for the arm for the other sail.

For Drum Winches.....

Now drum winches use the measurement of inches of pull (or winding). And they deal in continuous and non-continuous sheeting systems....

Here's some information I pulled from the Hitec RCD HS 725BB Sail Winch information sheet.

The following is copyrighted by Hitec RCD, used with permission.

For a "continuous" sheeting system (figure A,B,C), both sections of the drum are used, so that the ends of the "loop" feed on and off the spools at the same rate. In addition to the number of turns required to trim the sail, place a extra half to full turn of string on the spool. In this example, the sail winch and its drum are located under the deck of the boat. Pulleys are used to allow the string to exit the deck and turn with little friction.

A lot of what he's trying to learn is also dependent on his frame of reference and what he already knew about RC yachts and sheeting systems.

Several factors determine whether to use one or the other, How is the boat going to be used? Full out racing or more of a fun boat? How much does the skipper have to spend on radio gear? Also this really depends on the set of sails and the wind conditions you're going to sail in. And how complex a building / rigging job do you want? But, here goes.

I'll try my best to help, culling information from some good sources, Model Yachting Magazine issues #119 and #120 both reference one meter class boats, the US1m and Soling 1M respectively.

The details as I know them. The US 1M is limited to 600 Sq in of sail area, the Soling 1m is rated at 592 sq in of sail. Both boats can be configured with either a drum or sail arm sail winch.

Sail arm seems to be preferred in the Soling 1M, I presume for ease of construction and installation and to save money. The same should apply to US 1M's, though I saw many drum winch servos at the US 1M National Regatta in San Diego in August of 2000.

A Soling 1m article in MY issue #120 mentions the use of the Futaba 3801 arm winch and says it's too fast, but not enough rotation. But, in MY issue #119, Rich Dannenhoffer had an article on how to easily convert the Futaba 3801 sail arm servo from 90 degrees to 180 degrees of travel.

Now personally, I have a Soling 1m with a Victor sail winch and agree that it seems to have too little travel, but I sail and have fun with it. It just doesn't let the sails fully out in a full 90-degree wind on wing, though I can get a wing on wing. Some articles I've read say you don't really need that full 90 degree sail opening.

I have a US 1M coming they recommended the Hitec 725BB Drum Winch Servo since I prefer Hitec products and wanted to try a drum winch setup in a one meter, just my choice.

It's rated (using a 6V receiver battery like the Hobbico NiMh batteries, which can be fully charged with any 4.8 receiver battery charger, just takes longer) to do 3.5 turns, does 1 turn every 1.3 seconds and has 193oz/in+ torque.

> Does speed of the servo matter?

Yes, if you want to sheet in faster you need a faster servo. But remember to compare oranges to oranges, some servo ratings are at 6 V and some are at 4.8 V.

> Any advantage or disadvantage to a drum winch other than cost.

Drum winch setups can be rigged in a narrower space. The complexity of the rigging seems tougher for some skippers in dealing with drum winches, though some arm winch setups with double (or greater purchase) get to be more complex than any drum arrangement.

> What about the degree of travel?

This is in reference to a sail arm servo, and this can also depend on the boat the servo is being setup in. And it's controllable by several factors, simple geometry (a long arm will pull more sheet in, a double purchase setup will pull even more. There are some simple conversions that can adjust the degree of travel and some plug-in electronic devices that can adjust the degree of travel, some radios even have adjustable end points.

Remember, (or learn) there's a difference between a single arm setup and single purchase, and between a double arm setup and double purchase. The Soling 1m single arm setup on the You Asked page has a single purchase for the jib sheet and a double purchase for the main sheet, but a single arm setup. CR-914's come with a single arm sail servo, and use a single purchase setup too.

If it's a wide boat then a double arm can be used and a long arm can be mounted to it. I've even seen an offset double arm where the side of the arm feeding the main was longer than the side feeding the jib.

Determining Winch Arm Length

(From MY #66, Credited to Don Prough of Probar Design)

1. Connect the sheet line to the boom in the manner you plan to use while sailing.

2. Run the line into the boat through the fairlead.

3. Hold the boom in the "full in" position, and make a mark on the sheet line at the point where it enters the fairlead. Obviously, the line should be taut, and four hands are better than two!

4. Hold the boom in the "full out" position and make a mark on the sheet line as before.

5. Measure the distance between the two marks and:

a. For a single purchase arrangement, divide the distance by two, This is the length of the winch arm from the center of your winch's output shaft to the center of hole in the arm though which the sheet line will pass.

b. For a double-purchase arrangement, divide the distance by four and

add 1/4 inch to the result. This is the length of the winch arm from the center of your winch's output shaft to the center of hole in the arm though which the sheet line will pass.

6. Repeat the process for the arm for the other sail.

For Drum Winches.....

Now drum winches use the measurement of inches of pull (or winding). And they deal in continuous and non-continuous sheeting systems....

Here's some information I pulled from the Hitec RCD HS 725BB Sail Winch information sheet.

The following is copyrighted by Hitec RCD, used with permission.

For a "continuous" sheeting system (figure A,B,C), both sections of the drum are used, so that the ends of the "loop" feed on and off the spools at the same rate. In addition to the number of turns required to trim the sail, place a extra half to full turn of string on the spool. In this example, the sail winch and its drum are located under the deck of the boat. Pulleys are used to allow the string to exit the deck and turn with little friction.

For a single "non-continuous" sheeting system (figure D), where tension is maintained by elastic, either spool can be used. In addition to the number of turns required to trim the sails, place a extra half to full turn of string on the spool. Run the string from the drum, through a pulley that allows the string to exit the deck. Attach elastic to string on the deck to keep tension on the string as winds on and off the spool.

My thanks to Hitec for the use of this information.

Here's an alternative sheeting system using a Drum winch

Here's an alternative sheeting system using a Drum winch

Some sail arm setups use single arms, like the Soling1M, CR-914, stock Victoria, and many others, some use double arms like those depicted below.

What is the difference between a single purchase Sail Arm servo

arrangement and a double purchase sail arm servo arrangement?

Here are two graphics that depict the visual difference.

What is the difference between a single purchase Sail Arm servo

arrangement and a double purchase sail arm servo arrangement?

Here are two graphics that depict the visual difference.